DXF DESIGN & PROJECT PICTURE SHARING FORUMS.WELCOME CENTER, GOOD INFO & MEET OUR SPONSORS.I am also in the process of trying to build my own powder coat oven, heated via an indirect oil fired space heater which is probably more fundamental at the moment to my business I am now re-considering my first thoughts of "fabing up my own light weight 2 jaw chuck" would be a better option, more work short term but maybe a better long term answerĪs per my other posts I will as time goes along, post pictures and updates as things progress, but I do intend sitting back in a comfy chair, visulising the build and maybe a bit more pondering with a mug of tea (a very British way of working things out ) I did acquire a 150mm (6") 4 jaw self centering chuck, but the weight is 9Kg (20 lb) so I am now pondering that that mass is a high + the rest of the gearbox internals so the "smooth, responsive" part of my design spec might be under question I am now turning my attention to the mechanics of the attachment, trying to come up with a set up that has minimal mass to minimise the inertia requirements of the rotary axis, hopefully to achieve a smooth, responsive attachment capable of holding round, square and rectangular profiles, should be easy, compared to what I know will required in the next steps of actually producing good product. I am struggling at the moment trying to work out the axis orientation in the simulation as it is running to match them to the orientation that I want to set up my tube cutting attachment on my machine, I am sure I will grasp it soon (early days yet)

#SHEETCAM ROTARY LICENSE#

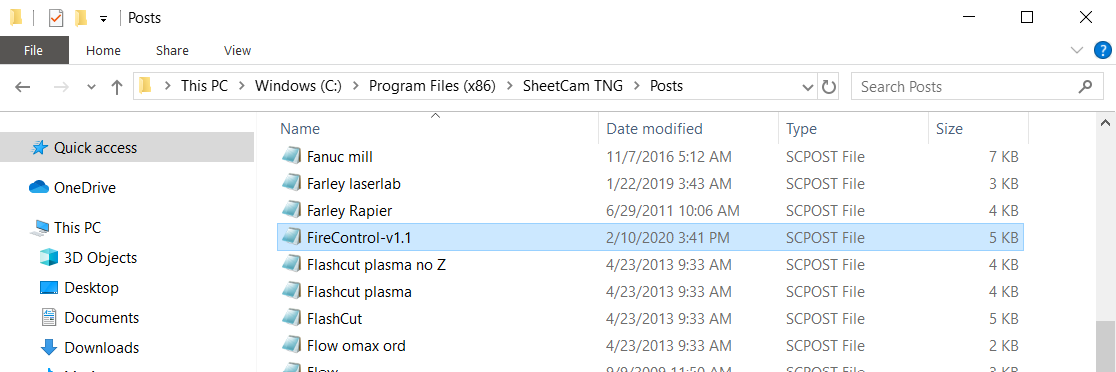

I have installed the license and have been able to run these test files through the SheetCam simulator and all is looking good I have now purchased the rotary plugin from SheetCam, done some CAD work and knocked out some simple test files (for square tube).

Looking forward to dialing it all in (I think ) In my reckoning that means about 77 rpm top end Using my existing PM 45 & machine torch (that is pretty much worst case, I believe ) Just thinking allowed I will post pics of the build during its progress so everyone could benefit (if your thinking also about a rotary axis)Īm I right in thinking I should base the rpm on achieving my fastest cut speed required on the smallest diameter to be cut and work back through the gearing to the optimum stepper RPMĪllowing for the unknown future requirements lets base it on a material thickness of 0.9 mm (0.0354")mild steel CR = 9652 mm/min (380"/min)

#SHEETCAM ROTARY DRIVER#

I have sourced a self centering 4 jaw chuck so the first stage will be some form of gearbox to mount motor and chuck but I am going to need an additional stepper and driver and maybe a new power supply hence the RPM question. Only guesstimating but I would think my tube dia would be max approx 150 mm (6") and the minimum dia around 40 mm (11/2") same for the box but adding in 100 x 50 mm (4"x 2") rectangular section, wall thickness from 2.5 mm (3/32") up to 10 mm (3/8") So this is the early stage of planning and my first question is - what is the ideal RPM I should be aiming for on the rotary axis My machine runs on CandCNC MP3500 ethercut, which will give me 5 independent axis in total, I am using 4 for my table that leaves 1 for my chuck drive My intention is to build a rotary attachment to cut both round and square tube. New year is nearly here and I am getting restless with too much time on my hands during the holiday!!!

0 kommentar(er)

0 kommentar(er)